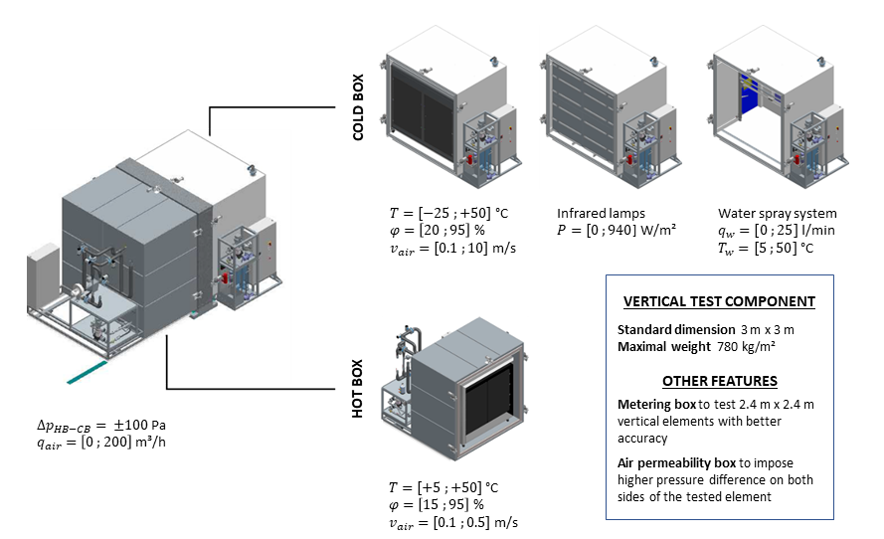

HAMSTER is a new hot box – cold box testing facility located in Greenbizz, Brussels. This equipment is used to conduct HAM-test of 3 m x 3 m walls, or flat or inclined roofs. The equipment is made of two climatic chambers: a cold box to reproduce exterior climate and a hot box to simulate interior conditions. It also includes numerous features to reproduce rain, pressure difference or infrared radiations. With this testing facility, Buildwise aims to create a strong connection between research and practice, and to foster innovation in the building sector.

HAMSTER and its features

HAMSTER is made of three different parts: the hot and cold boxes, and the test frame. In addition, an air permeability box can be used with the test frame for airtightness testing of the components.

-

The Cold Box is used to reproduce exterior climate. In addition to the control of air temperature, relative humidity and air speed along the tested wall, rain and surface temperature can be controlled with infrared lamps and water spray system.

-

The Hot Box is used to reproduce interior conditions. Air temperature, relative humidity and air speed along the tested wall are controlled. In addition, an airflow can be induced in the hot box in order to create a pressure difference between both chambers.

-

The wall is built within the test frames, which is then placed between both chambers to be tested. Small test frames (0.6 m width) are used for vertical walls while larger test frames (3.6 m) are specific for inclined and flat roofs.